Since May 2020, EUBIA has animated the stakeholder platform BIOCOGEN 2030, which wants to be a flexible and open forum where companies and Universities working on small-medium scale CHP from biomass can meet, discuss and create opportuinities. During the European Biomass Conference and Exhibition 2020 there will be a dedicated online webinar on BIOCOGEN 2030, outlining some innovative solutions and experiences in the field of CHP from biomass. However it was not possible to include them all, this is why EUBIA has decided to create this page, showcasing some additional biomass CHP solutions developed by European companies of the BIOCOGEN 2030 community.

Here you will find information on:

AHT SYNGAS TECHNOLOGY N.V.

BIOLIZA

ENTRENCO

About the company

A.H.T. Syngas Technology N.V. specializes in planning, engineering, delivery and support of syngas, heat and power generating biomass plants. Due to the unique twin-fire technology with two gasification zones, a broad range of biomass can be applied. Even sewage sludge, manure and digestates can be used – by a carbonisation technology which generates a coal-like feedstock, perfectly suitable for subsequent heat and power generation. A wet gas scrubbing ensures an exceptional pure syngas, applicable in high-efficient CHP’s. Co-generation at its best: Base load capacity for decentralised power and process heat supply for industries, agriculture/husbandry and municipalities

Products and solutions

A.H.T. delivers biomass-to-heat&power plants in the range of 200 kWel up to 12 MWel. Also hot and clean-gas solutions are available, starting from 400 kWth up to 50 MWth. Application can be industrial processes in need of heat and steam, greenhouses, stables, food & beverage industries, porcelain, glass and lithium processing industries – to name a few.

Further, A.H.T. supplies hydro- and vapothermal carbonisation facilities. By means of pressure, heat and time, a coal-like feedstock emerges, perfectly suitable for subsequent syngas generation. This way, high-moisture biogenic residues such as sewage sludge, food waste, digestates and manure can be utilised. Espcially sewage sludge treatment plants now have a chance to operate energy-independently and climate neutral. Pre-drying is not necessary, lowering considerable energy costs. The formed hydro char is also usable as soil improver. The remaining water typically contains valuable fertilisers and can also improve biogas plants efficiency.

And there is more: Currently, A.H.T. lookls into hydrogen separation from syngas. As syngas already contains H2, it does not need to be synthesised by means of extensive energy consumption – a truly green hydrogen!

Media and resources

Brochure: gas heat and power generation from biomass

About the company

BIOLIZA is a Spin Off from the University of Jaén (Andalusia region, Spain) established in April 2014 and specialized in developing solutions for residual biomass energy valorization.

The main services BIOLIZA provides are the following:

- Engineering and Consultancy.

- Training (Master, courses, seminars, …)

- Development of turn-key projects, mainly based on gasification technology in self-consumption mode.

Our clients are private companies and public institutions interested in finding a solution for its residual biomass, to show their commitment to generating sustainable added value (costs and CO2 emissions reduction).

Products and solutions

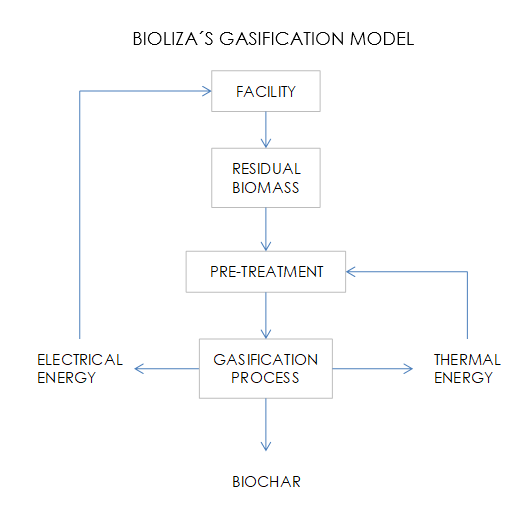

Our main solution for residual biomass energy valorization is gasification in self-consumption mode.

For it we do the following:

- A previous analysis of the biomass generated: quantity, seasonality, etc.

- A exhaustive study of the energy consumption of the facility (thermal and electrical)

- A physical and chemical biomass characterization (LCV, Humidity, ash content, grain size, …)

- A dimensioning of the gasification installation (energy and mass balance)

- An economical and financial feasibility analysis (Capex, Opex and IRR)

- A management project: authorizations and administrative Permits, integrated environmental assessment, subsidies, engineering, systems integration, etc.

The objective is give to the client a global solution which contains all main issues for decision making from the energy, economic and environmental point of view, under a model like the following:

About the company

ENTRENCO has 13 years of experience in power/heat generation from biomass and has been awarded for innovation. We produce CHPs, Combined Heat and Power Units, based on wood pellets and wood chips with an output of 50 kWel and 120 kWth.

We have the future in mind We convert innovative concepts for energy generation from biogenic waste materials, currently mainly from forestry, into increasingly efficient solutions.

We have high expectations With our “Plug & Perform” approach, we want to give our customers easy access to environmentally friendly energy and heat supply.

Technology In our new Development Center in Eching near Munich, our CHP (= Combined Heat and Power) products for wood chips and pellets are continuously being developed further in the direction of higher stability and durability as well as lower operating costs.

Products and solutions

Small CHP units, three versions:

Nominal output: 25 kW of electricity and 60 kW of heat

Feedstock: DIN EN Plus 6 mm A1 or certified

E-Fuel biomass waste pellets

Consumption: 20 -23 kg/h*

Electrical efficiency: 25%*

Thermal efficiency: 60%*

Temperature of heat output: 90°C / 60°C

Operating hours: up to 7500 h/a**

Control unit: Fully automated, 24/7 remotely monitored

Installation: 20 ft. container or in-house line-up

Nominal output: 50 kW of electricity and 120 kW of heat

Feedstock: Wood chips EN14961-1, P16-P45

Consumption: 45 – 47 kg/h*

Overall efficiency: 83%*

Electrical efficiency: 24%*

Thermal efficiency: 59%*

Temperature of heat output: 90°C / 60°C

(5.000 l/hr)

Electrical Output: 200V / 400V @50Hz,

400V @60Hz

Operating hours: up to 7500 h/a**

Nominal output: 50 kW of electricity and 120 kW of heat

Feedstock: Wood chips EN14961-1, P16-P45

Consumption: 45 – 47 kg/h*

Overall efficiency: 83%*

Electrical efficiency: 24%*

Thermal efficiency: 59%*

Temperature of heat output: 90°C / 60°C (5.000 l/hr)

Electrical Output: 200V / 400V @50Hz, 400V @60Hz

Operating hours: up to 7500 h/a**