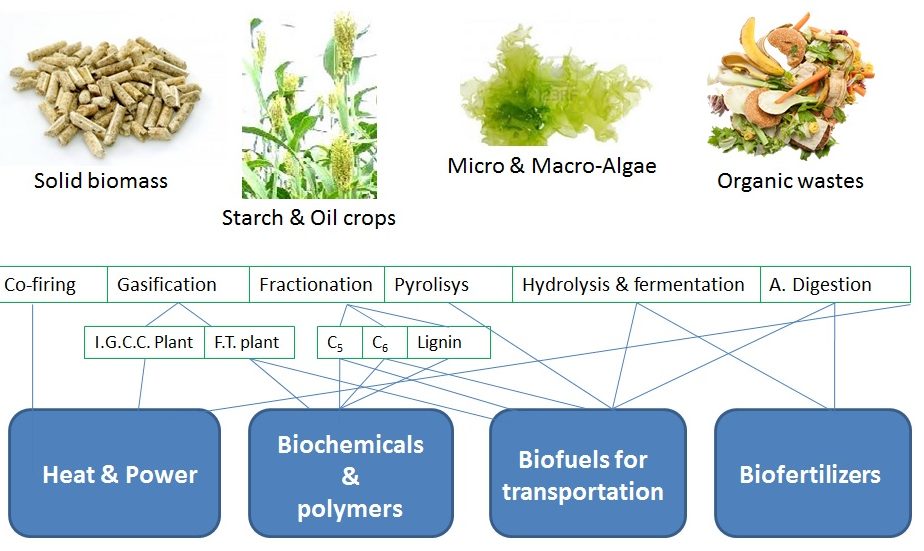

There are 6 generic biomass processing technologies based on:

- direct combustion (for power)

- anaerobic digestion (for methane-rich gas)

- fermentation (of sugars for alcohols)

- oil exaction (for biodiesel)

- pyrolysis (for biochar, gas and oils)

- gasification (for carbon monoxide and hydrogen-rich syngas).

These technologies can then be followed by an array of secondary treatments (stabilization, dewatering, upgrading, refining) depending on specific final products.

The wide range of biomass sources available in nature includes feedstock characterised by different chemical compositions, physical status, toxicity and energy content. The feedstock quality represents a relevant aspect influencing the decision on the most suitable valorisation technology to be adopted. In particular, despite the energy recovery efficiency should represent the key driver for the choice, economic competitiveness and market opportunity play the main role towards the commercial development of new technologies and strategies.

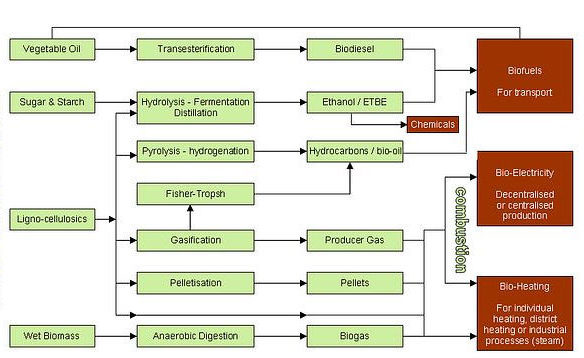

The energy available in biomass may be used either by direct use as in combustion, or by initial upgrading into more valuable and useful fuels such as charcoal, liquid fuels, producer gas or biogas. Thus, biomass conversion technologies can be separated into four basic categories: direct combustion, thermo-chemical conversion processes (pyrolysis, gasification), bio-chemical processes (anaerobic digestion, fermentation) and physico-chemical (the route to biodiesel).

Woody biomass co-combustion with coal, or direct combustion is by far the most developed sector in Europe and worldwide. However, transportation biofuels produced from lignocellulosic residues from agriculture and forestry, as well as biogas or bio-syngas produced via thermochemical or biochemical treatment of liquid and dry biowastes are emerging sectors which are attracting several industry key actors.