The existing challenges of biomass supply chain related to different feedstock can be broadly classified into operational, economic, social and policy and regulatory challenges.

Operational Challenges

Feedstock unavailability: Inefficient resource management and the government non-intervention approach are the key factor hindering the expansion of the biomass industry.

Regional and seasonal availability of biomass and storage problem: The seasonal variation results in the fuel price. As the energy density of biomass is low, acquisition of land for harvesting and storage is difficult.

Pressure on transport section: Because of biomass moisture, transporting wet biomass from the plantation to the production site becomes energetically unfavorable and costly with increasing distance.

Inefficiency of conversion facility, core technology and equipment shortage: Technical barriers were resulted from the lack of standards on bioenergy systems and equipment, especially where the energy sources are so diverse. Appropriate pretreatment required to prevent biodegradation and loss of heating value, not only increases the production cost but also in equipment’s investment.

Immature industry chain: It is virtually impossible to get long term contracts for consistent feedstock supply in reasonable price. The low ability to gain profits is also a reason that many upstream firms lack driving forces in the technology reform.

Economic Challenges

Feedstock acquisition cost: The biomass resources are scattered and in order to reduce the cost of transportation, biomass projects are eager to occupy land close to the source, leading to centralization of biomass projects.

Limiting financing channels and high investment and capital cost: Because of decentralized capital, poor profitability, frequent fluctuations of international crude oil prices and high market risk, seldom investors took an initiative part in the biomass power generation industry.The biomass power generation is subjected to constraints of excessive investment and high operating costs. Biomass pre-treatment technologies have extra costs, which scattered farmers and small scale fuel companies may not be able to afford.

Social Challenges

Conflicting decision: Decision making on selection of supplier, location, routes & technologies is crucial and needs proper communication. By strengthening leadership and implementing the responsibilities, the stakeholders should be made fully aware of the economic, environmental and social wealth of resource utilization.

Land use issues: Land use issues leads to the loss of ecosystems preservation and the homes of indigenous people.

Impact on the environment: The biomass plantation depletes nutrients from soil, promote aesthetic degradation and increase the loss of biodiversity. Other social impacts will result from installation of energy farms within rural areas like increased need of services, increased traffic, etc. The potential negative social impacts appear strong enough to ignore the benefit of new and permanent employment generation.

Policy and Regulatory Challenges

Policies: At present, the government is subsidizing the domestic fuel price which in turn makes the electricity

generating cost from conventional sources lower than the power production cost from renewable fuels.

System: There are no specific rules to regulate the work of utilization of biomass resource, and there are no specific penalties for not using behavior that should be comprehensively used.

Regulation: There is no special mechanism to manage the development of biomass resources industry and no specialized department to manage the implementation of relevant national standards and policies.

Source: Aryama Raychaudhuri and Sadhan Kumar Ghosh. Biomass Supply Chain in Asian and European Countries. Procedia Environmental Sciences 35 ( 2016 ) 914 – 924 .

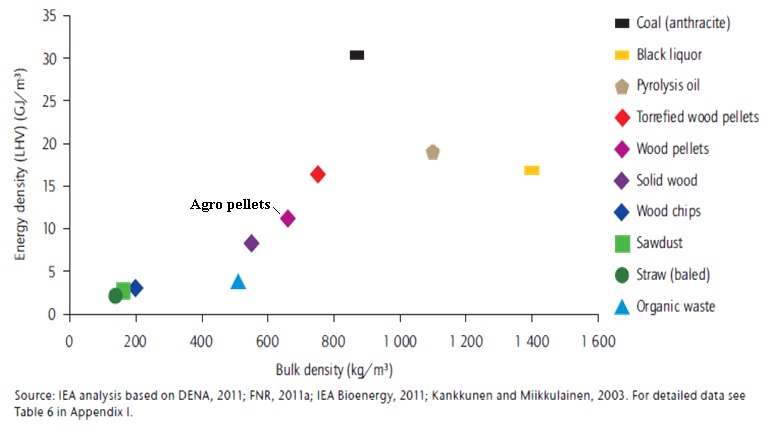

Problems of biomass large scale supply

One of the biggest problems related to biomass large scale supply is the energy density. Briefly, if biomass moisture of conventional wood is 30%, this means that every 1 ton of wood transported, 300 kg are water. Additionally, biomass feedstock shape (chipped, pelletized, rounded, baled), strongly influences the bulk density and affect the transportation economics. For this reason, compaction and densification are considered crucial for an efficient biomass supply. The figure below shows the energy density and bulk density of different biobased feedstock.

In addition to the bulk and energy density, large scale biomass supply is affected by a wide range of bottlenecks including raw material initial cost, biomass producers involvement, environmental regulation and sustainability. Finding solutions for all these problems means finding the solution for the creation of the future biomass commodity in Europe and worldwide.

|

PROBLEMS |

SOLUTION |

| High quality biomass (wood) is considerable but limited expensive and not always sustainable | Utilization of agro forestry residues. High availability and fully environmentally sustainable |

| Agro-forestry residues have lower quality and higher micro-elements (K, Ca, Mg, ashes) content | Blending of different biomass feedstocks to arrange suitable average composition |

| Availability is mainly reduced to forests areas | Residues have much lower costs and dispersed and available almost everywhere |

| Low energy density and bulk volume (KJ/m3) of fresh biomass affect storage costs and transportation efficiency | First step chipping activities, enhance biomass energy density increasing transportation efficiency |

| Biomass degradability affect large distances transport activities, long time storage | Agropellets production, with low moisture and high energy density. Avoiding degradation and transportation issues. |